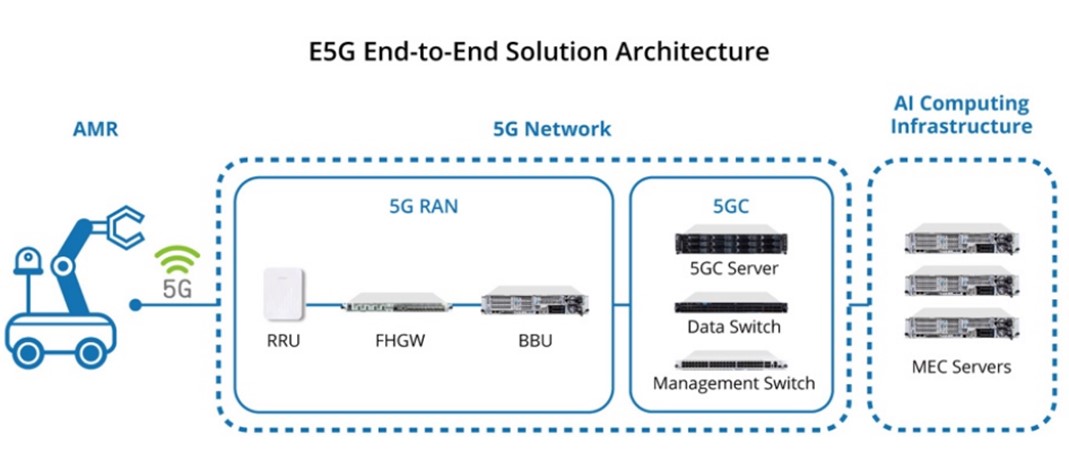

Under the guidance of Taiwan’s Industrial Bureau of the Ministry of Economic Affairs and in alliance with local manufacturers like QCT and Panasonic, companies can effectively reduce error rates and improve the overall production capacity. In 2021, Panasonic applied to Taiwan’s National Communications Commission (NCC) for 5G experimental frequencies and upon obtaining approval they would carry out field intelligence at their Zhonghe plant.  Fig 1. QCT E5G Solution Architecture With the integration of QCT’s enterprise 5G private network equipment and AR/VR technology they were able to create an intelligent manufacturing auxiliary system suitable for various fields. Over the years, QCT and Panasonic Taiwan have been great complements to each other in expanding enterprise 5G businesses. Their first successful n79 standalone 5G PoC came in the form of smart manufacturing of car headlamps and server motherboards, and they also enabled smart agriculture with their reliable, agile, and cutting-edge enterprise 5G solutions.

Fig 2. Mixed Reality overlay on PCBs at Panasonic Taiwan Focusing their efforts to use the characteristics of high-speed transmission and low latency of enterprise 5G private networks, they are helping field operators improve the quality of operations with mixed reality (MR) and artificial intelligence (AI) technology. At the Panasonic Zhonghe plant, Panasonic together with QCT have built an autonomous mobile robot (AMR) automated system that assists in the handling of raw materials in their production line. Overall, this system achieves the goal of reducing manpower and creating timely production rates. Furthermore, the AMRs are also equipped with 360-degree panoramic cameras, which can also simultaneously carry out factory inspections when handling materials and use AI image identification to monitor whether there are abnormal warnings such as fire and smoke to ensure workplace safety.  Fig 3. AMR equipped with 360-degree panoramic camera utilizing AI technology |